SAVANT AGV System:

5 AGV Types Seamlessly Operating

In One ‘Virtual’ Path System

Are You Thinking About

About Buying a

Guided Vehicle System?

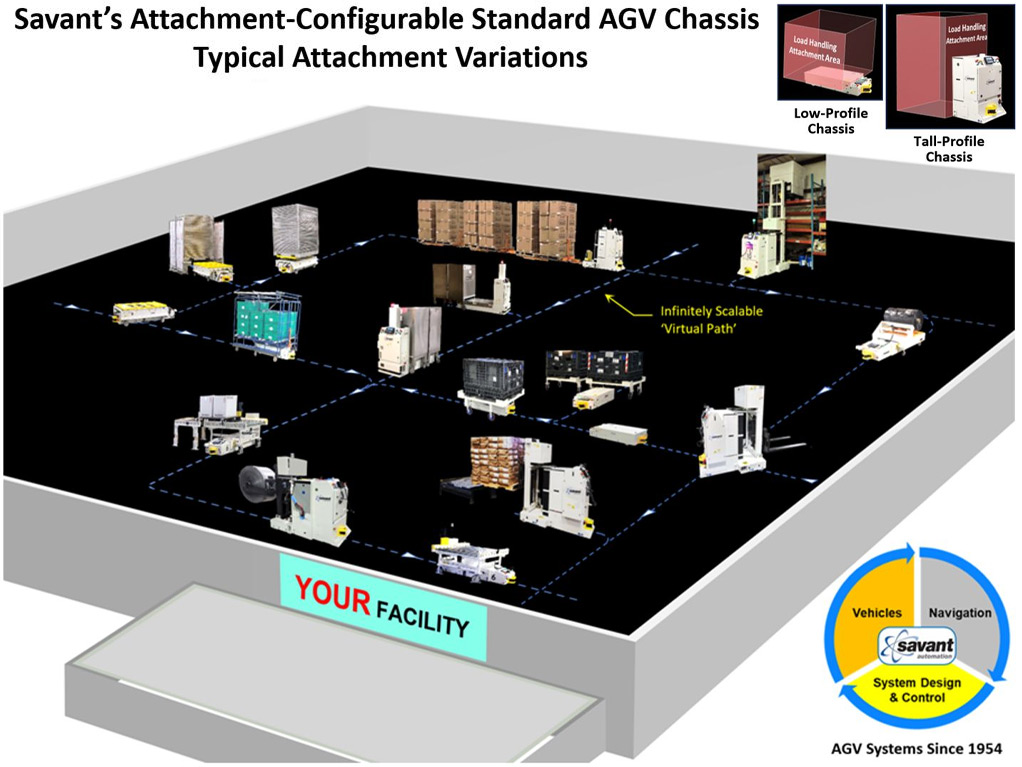

Which Guided Vehicle (AGV, AMR, AGC) Design Strategy Offers Greater User Benefits, Standard or Custom Chassis?

There are many differences between suppliers of AGVs, AGCs, and AMRs.

One CRITICAL difference for an end-user to consider before purchasing, is whether…….

1. ‘Custom’ design vehicle – A supplier’s vehicle necessitates that the load handling mechanism be uniquely engineered & integrated into base vehicle chassis structure, thereby customizing/modifying the chassis.

2. ‘Standard’ design vehicle – The supplier’s vehicle load handling mechanism is an independent attachment to a common/unchanging vehicle chassis.

There are several USER benefits that with the ‘standard’ design vehicle product approach.

Read More...

· It allows the guided vehicle to be repurposed/reused in a different configuration if the user wishes to employ the units in a different application (reusable asset). A ‘custom’ design guided vehicle is pretty much limited to the original application and very difficult/expensive to repurpose.

· It provides greater reliability than an ‘custom’ type vehicle because the ‘standard’ design is well-proven in many other users.

· The ‘standard’ vehicle is more affordable because it is built in higher numbers (over a broad user base) than one-time ‘custom’ design types.

The graphic above illustrates the versatility of Savant’s standard vehicle design with customer images of our ‘attachment-configurable’ base vehicles.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

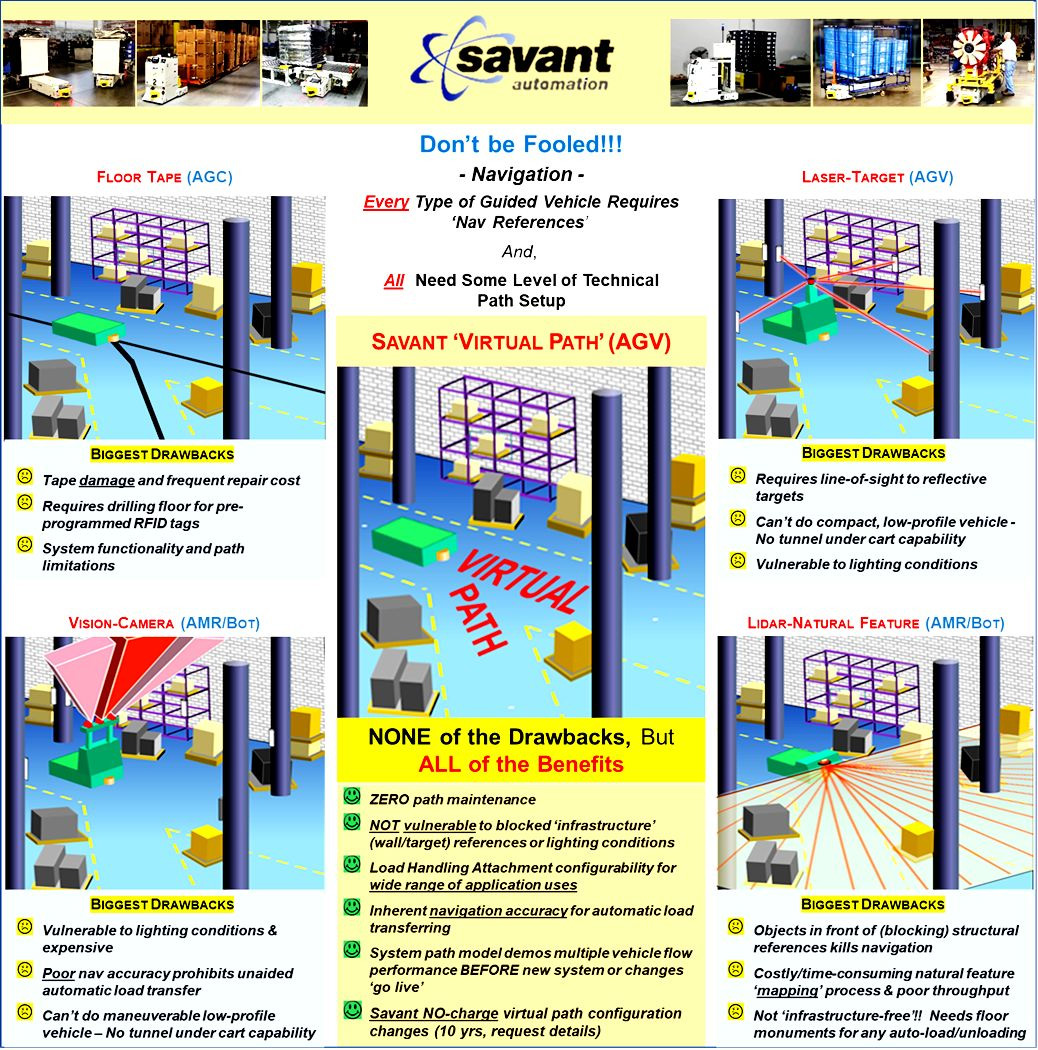

Don’t be Misled… ALL Guided Vehicle

Navigation Depends on Some

Type of Fixed Reference

Using the wrong navigation technology / references in your facility environment will result in random stopping of the guided vehicles in YOUR system.

In factories and warehouses, navigation reference vulnerabilities will make or break a guided vehicle system. These vulnerabilities include damage to the references, random movement of objects that block the guided vehicle from seeing its references (i.e. surveyed building structure), variable lighting conditions, dust accumulation on vehicle navigation sensors, uneven/cracked floor surfaces, etc.

These vulnerabilities exist with Lidar and Vision type AMR (autonomous mobile robot) vehicle navigation systems making AMRs a poor choice for factory and warehouse environments. These vulnerabilities do NOT exist with Savant ‘virtual path’ navigation used on Savant guided vehicles, making our AGVs a good choice in these application environments.

Read More...

Savant AGVs ‘bulletproof’, virtual path navigation. Our navigation references are small in floor markers that never fail, cannot be blocked and take only minutes to install. That means our AGVs are not subject to random stopping due to reference vulnerabilities. AND… whereas AMR navigation is generally inaccurate without additional infrastructure (physical targets), Savant AGV navigation is always accurate without dependence on additional target aids.

If your factory or warehouse guided vehicle system includes Automatic Load Transferring performed by the vehicles at various destinations, know that ARM/natural feature navigation alone can Not provide the tracking accuracy required align with conveyors, properly position with robots, fork-engage with loads on the floor or in racks, do automatic hitching, tunnel under carts, etc. Savant AGV do this with ease and with no additional infrastructure (physical navigation aids).

The purpose of this video is to show typical, real factory and warehouse system applications using Savant AGV where AMR vehicle navigation technology is not appropriate because of their reference vulnerabilities. That is why most material handing type AMR videos on YouTube or LinkedIn are either ‘staged’/not real or animated graphic system representations (cartoons) and also why there are so few, if any real-world videos of AMRs in applications comparable to those shown this 35 Savant AGV system examples in this video.

SEEING (real systems applications) NOT HEARING (sales hype) IS YOUR BEST INSURANCE FOR CHOOSING THE RIGHT GUIDED VEHICLE SYSTEM TECHNOLOGY FOR YOUR FACTORY OR WAREHOUSE SYSTEMS APPLICATIONS.

US-based, Savant develops and owns its AGV technology and manufactures our unique universal-use vehicles. We are a full service AGV/AMR system supplier providing all project services as well as 24/7 aftermarket support.

Our history began in 1954 with the invention of the AGV. ISO-certified, we have supplied systems for manufacturing, warehousing, distribution, paper, plastic, pharmaceutical, food, beverage, healthcare/hospital, etc. markets.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

SAVANT Fork AGV System

Transporting Full and

Collapsed Parts Baskets

Separating ‘the AGVs from the AMRs’ (the Men from the Boys)

When you need a guided vehicle system to operate in a dynamic factory environment where solid, line-of-sight to ‘natural feature’ navigation references (walls) can NOT be guaranteed… Savant AGV ‘virtual path’ navigation is the solution.

Our simple, maintenance-free, trivial cost, navigation references can’t be blocked or affected by objects moving around (and blocking natural feature references) outside of the travel path or variable lighting, humidity, and dust conditions. That means the Uptime of Your vehicles and system is not impacted by vulnerable navigation references.

Read More...

This AGV system moves heavy parts baskets from production areas to the shipping dock and destacks empty collapsible pallets to replenish the parts production locations.

US-based, Savant develops and owns its AGV technology and manufactures our unique universal-use vehicles. We are a full service AGV/AMR system supplier providing all project services as well as 24/7 aftermarket support.

Our history began in 1954 with the invention of the AGV. ISO-certified, we have supplied systems for manufacturing, warehousing, distribution, paper, plastic, pharmaceutical, food, beverage, healthcare/hospital, etc. markets.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

AGV vs. AMR vs. AGC

Navigation

Don’t Pick the Wrong Type for Your Application & Facility Environment

TRUE OR FALSE…

AGVs, AMRs, and AGCs are equivalent and equally capable regardless of the facility environment and operational demands. FALSE!!

Automated Guided Vehicle (AGVs) , Autonomous Mobile Robots (AMRs) and Automatic Guided Carts (AGCs), ALL need Navigation References to operate. TRUE!

If a guided vehicle can’t navigate safely, it must stop. TRUE!

The type of Navigation Reference is the most critical factor impacting safe & reliable vehicle automated operation in a facility. TRUE!

Read More...

The type of navigation references used by a guided vehicle are critical to save & reliable vehicle navigation. TRUE!

Knowing the strengths & drawbacks associated with different types of guided vehicle navigation for your facility environment is the First & Most important consideration when evaluating guided vehicles for any application. TRUE!!!!!

If you don’t have bulletproof navigation, you don’t have a guided vehicle system!

Use this graphic when you’re evaluating a guided vehicle system for your facility.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

Versatile, efficient and affordable

solution for reducing forklifts

and material handlers

A fleet of over 30 Savant low-profile, ‘tape/target/structure-free’, virtual path AGVs automatically transports different size/purpose carts between hundreds of destinations.

Racks, totes, shelf, pallet, kitted and trash carts are moved on demand assuring labor-efficient, timely service to all plant areas. Unlimited scalability coupled with zero navigation vulnerability downtime has significantly reduced costly & non-value adding labor.

Another Attachment Type

Using the Savant Automation

Universal-Use AGV…

The lift/lower platform is powered by the low-profile AGV pinned underneath. This allows the AGV transfer loads to/from simple & inexpensive static load stands or conveyor with split roller/open center access.

Savant AGV support all functionality required for fully automatic, ‘hands-off’ operation. This includes failsafe interlocking with powered doors, light curtains, conveyors, and robots and interface with forms of station I/O that generate AGV pickup calls such as HMI’s, tablets, pushbuttons and load sensors at load pickup stations. The AGV system controller (PC) supports integration with upper-level control systems (MES, WMS, WCS, PLC networks, etc.) for remote AGV ‘call & dispatch’ operation.

Read More...

Note the traffic control functionality that permits multiple vehicle movement in tight, complex virtual path areas. Less capable technologies severely restrict AGV/AMR freedom of movement. The COST to you….poorer response time (longer load move wait times), lower system efficiency (less loads moved per hour per vehicle), all negatively impacting your facility’s operational performance.

Unlike natural feature/AMR type navigation, these AGVs do not need special stand or floor mounted steel bracket targets (monuments) to accurately position for automatic load pick or drop operations. So, there are no ‘trip hazard’ type navigation aids. Most importantly, Savant AGVs can maneuver in very tight spaces and perform exceptionally efficient traffic control that allows higher load move throughput rates than possible with other technologies.

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

Others talk about being able

to do many things

with their AMRs/AGVs…

They might even post a “staged” video. Savant “walks the talk”. These are real world ‘working’ systems that work in virtually any factory or warehouse environments.

Versatile, ‘universal-use’ chassis allows Savant utilize the same, proven AGV design for many different types of applications using powered load handling attachments appropriate for each customer’s needs. It’s only the load handling attachment that changes NOT the critical AGV. The less an AGV is custom designed… the better.

Customer benefits of a standard AGV ‘attachment-configurable’ chassis are… lower Price, more Reliable AGVs, less Maintenance, Proven performance, Re-Purposing same AGV for new applications (truly Reusable Asset), lowest system project Risk, most User-Friendly/User-Tolerant operation, and More.

Read More...

There is no substitute for guided/autonomous vehicle automation experience and given we invented the AGV in 1954, Savant has been in the business way longer than anyone. It’s why Savant’s AGV in-house developed technology (vehicles, navigation, control system) is rated so superior to all others.

In fact, most other AGV/AMR suppliers don’t make the core technologies in their vehicles/system. Rather, they license it from a disconnected 3rd party……think ‘obsolescence & support risk’. Savant supports its technology regardless of how old it is…….. because we develop every generation of our technology in-house.

Unlike natural feature/AMR type navigation, these AGVs do not need special stand or floor mounted steel bracket targets (monuments) to accurately position for automatic load pick or drop operations. So, there are no ‘trip hazard’ type navigation aids. Most importantly, Savant AGVs can maneuver in very tight spaces and perform exceptionally efficient traffic control that allows higher load move throughput rates than possible with other technologies.

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

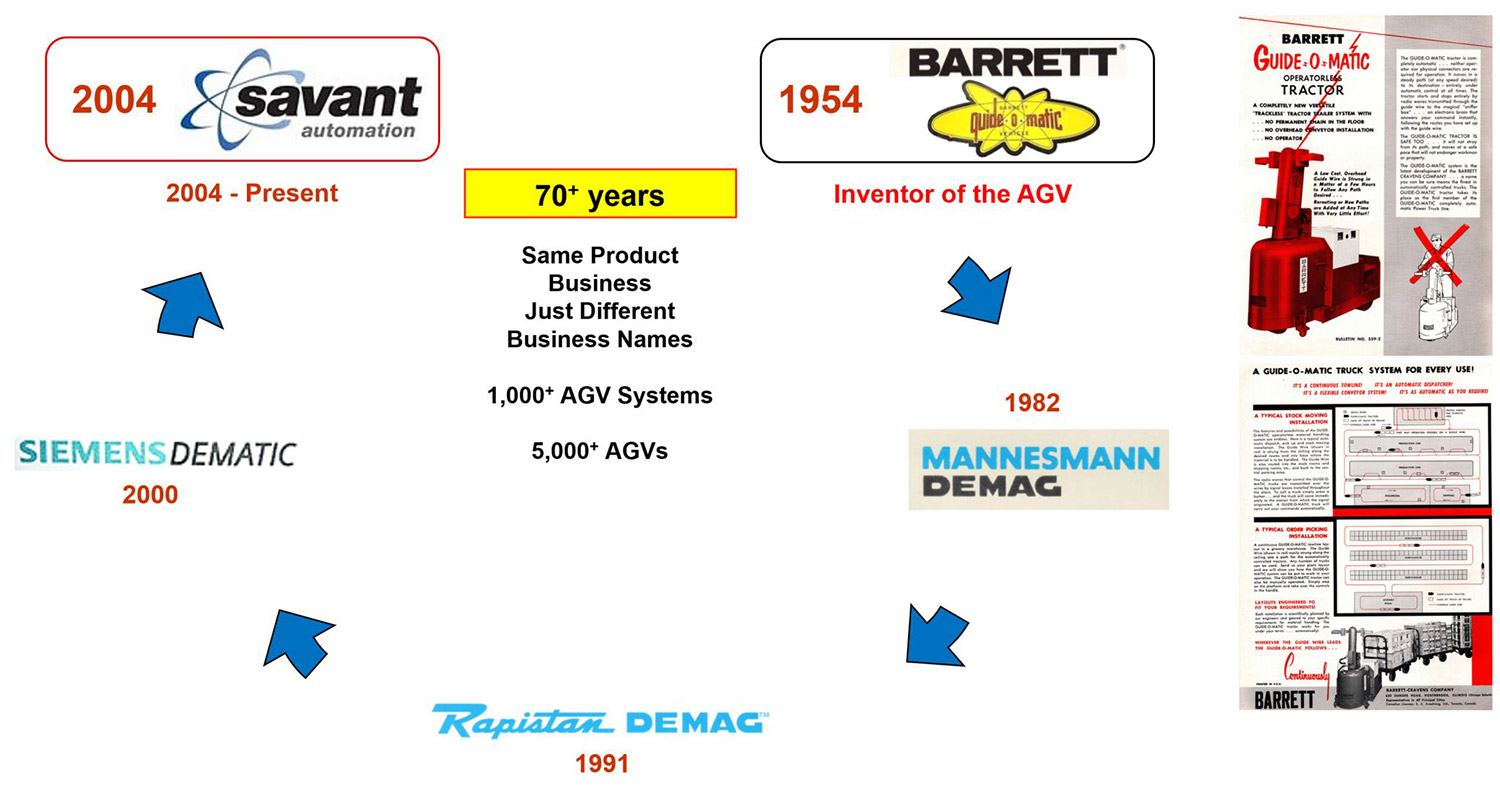

Over 70 Years

of AGV Experience

to Help Customers

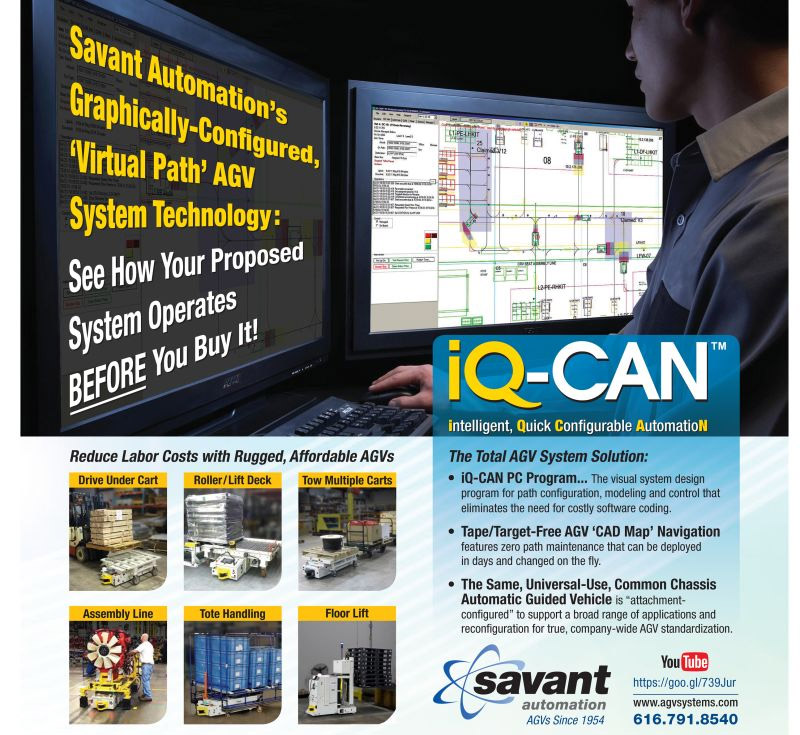

Savant continues to innovate using customer experience to create robust, flexible, “AGV Technology Truly Focused on the User.”

With over 70 years of AGV history, Savant continues to innovate using customer experience to create robust, flexible, ‘AGV Technology Truly Focused on the User’.

Our Virtual Path (CAD map) AGVs do NOT employ vulnerable Navigation references like floor tape, active RFID in-floor tags, reflective targets or often blocked, natural features (walls). This insures our customers have a maintenance-free system path of any size or complexity.

Vulnerable navigation references cause vehicles to randomly stop requiring user intervention or result in insufficient positioning for automatic load transfers. Savant references are ‘bullet-proof’ they can’t be blocked, nor do variable lighting, dust, humidity, uneven floors, etc. conditions affect (interfere with navigation operation or accuracy).

Read More...

We create our navigation path using a PC program to visually configure the path configuration, location of destinations, path actions, traffic control, etc. This results in a model of the system allowing users to see how their proposed system (or any changes) will operate BEFORE the purchase it. The file from the model drives the actual system so What You See is What You Get.

Savant creates you new system model at No-Charge. You get a written proposal and a ‘visual’ proposal (the model). This makes it much easier and quicker for management and operations staff to quickly understand (and support) the proposed system project.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

Precise Navigating

Savant AGVs Transport

Bulk Food Ingredients

Precise Navigating Savant AGVs Transport Bulk Food Ingredients to Food Processing Machines.

Standard ‘attachment-configurable’ Savant AGV chassis fitted with bulk materials container lifting device. These units transport bulk food ingredients between ingredient filling stations and food processing machines.

The AGVs follow a ‘virtual’ path (no floor tape, above floor reflective targets and no dependence on often block natural features/walls). The AGV navigation is ‘bulletproof’ and highly accurate for dependable automatic load transfer. The AGVs track an easily changeable CAD map so the path is maintenance-free and infinitely scalable.

The customer’s production control system generates ‘from/to’ product move directions to support the food processing requirements.

Read More...

This information is sent to the AGV system controller PC via Ethernet. The system controller assigns AGVs to execute bulk product move tasks to specific AGVs based on priority, location and availability. The mission assignments are communicated to the desired AGV via the existing the WiFI network.

AGVs are sent to the filling room and position the bulk materials container at one of the dozen overhead fill chutes. The AGVs elevate the container and signal the chute to open. The filling chute closes when the container receives the correct about of ingredient product. The AGV then lowers the container and travels to the assigned processing machine.

When the AGV arrives at the designated processing machine, it elevates the loaded container and positions it over the machine’s hopper. The AGV actuates the container’s door allowing the contents to fill the processing machine’s feed hopper. When the process is complete, the AGV is available for a new mission.

The AGV system ensures the processing machines are serviced quickly and eliminates any costly product delivery errors.

When it’s your navigation & control technology, your vehicles with your project execution and aftermarket support……you will always provide the best and most reliable system backed by the best long-term aftermarket support services. That’s why Savant has an uninterrupted 70-year history and why we’re the best in this business.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less

Savant Automation

Tunnel Under & Tow Cart

String AGV System

Versatility and Flexibility are Critical Factors When Choosing AGV Technology!

AGV, AGV and AMR navigation schemes all have their benefits and drawbacks but do NOT overlook the very important ‘Vehicle & System Technologies’ associated with these various navigation schemes… they can CONSTRAIN what you can do in the future with your system.

‘Versatility’ and ‘Flexibility’ are critical factors when choosing a guided vehicle technology.

Beyond the type of Navigation, it’s the guided vehicle suppliers’ Vehicle & System Technology that makes the vehicles operate as a ‘system’ in your facility. It can either limit or increase the ‘bang for your buck’ of your capital investment depending on the level of versatility and flexibility that technology provides.

Read More...

This system employs Savant low-profile AGVs to automatically connect to a string of carts, tow to and leave them at new location. The AGVs just reverse under the lead cart, lock to it by extending a pin into plastic block attached to the underside of the cart then, switch to forward travel to transport the cart string to a new destination.

The hitching and unhitching of the cart string is simple, inexpensive and very reliable. The AGVs can move single or multiple carts as needed in different areas of the facility… all without operators needing to be present.

The path is ‘virtual’ and 100% reliable because the vehicle navigation does NOT employ tape, targets or depend on people maintaining clear ‘line-of-sight’ to walls or other ‘natural feature’ navigation references. An easy to change map file the vehicles follow allows unlimited system expansion and change flexibility.

Savant’s one-of-kind combination of Navigation, Vehicle and System Technology provides the most versatile, flexible, reliable, and affordable guided vehicle system solutions compared to what others offer.

Use the Quote Form, available on our website, to provide the information that will allow us to propose the optimal guided vehicle system solution for your needs.

CONTACT: 616 791-8540

Less

Precise AGV Navigation

for Robotic

Interface

Talk is Cheap……This is Where the Rubber Hits the Road!!!!

Here’s our tall-profile AGV with a unique load handling attachment designed to move special racks with molded parts between robotic cells. The AGV is our standard chassis with only the bolt-on load handling attachment/appliance at the rear of the chassis being unique to each customer depending on their load handling requirements.

Here the attachment is a special hook arm with a ‘capture & lock’ mechanism on the end that picks or deposits a hanging rack of molds at each automated robot station. Part of the AGV load attachment is the forklift-like mast that allows the hook arm to service mold ‘trees’ at different heights at each station.

Read More...

The operation requires extreme AGV positioning accuracy to maintain the ‘robot to robot’ tolerances of the multi-step manufacturing process. Savant’s ‘Virtual Path’ AGV navigation enables the multiple AGVs to reliably perform the necessary positioning with no tolerance buildup between moves.

You can’t do these automated vehicle systems with AMR type technology. AMR (Lidar-laser and/or Vision-camera based) navigation requires walls be scanned (mapped) for use as navigation references. If the AMR can’t see those mapped references reliably (because they are randomly blocked by other objects), the AMR navigation accuracy rapidly deteriorates and it can’t align with automatic load transfer stations or worse, it will have to stop. That can’t happen with a Savant AGV because our references (a tiny magnet placed flush in the floor) can’t be blocked or fail so ‘reference vulnerability’ is not an issue like it is for natural feature (line-of-sight, wall reference dependent navigation) AMRs.

A robust ‘system’ is not just about robust ‘vehicles’… it’s also about robust ‘technology’. Technology ‘robustness’ is critical to attain a high level of system dependability/capability/flexibility/people & environment tolerance/ease of change/serviceability, etc. Suppliers have different designs for the interrelated technology functions for navigation, traffic & routing control, system configuration, and system management. Some better than others but all directly impact the robustness of a system.

Technology is “what you don’t appreciate until it bites you in the butt and negatively impacts your day-to-day operations (i.e. output & costs)”. That why an AGV technology-based solutions broadly work in factories and warehouses and AMRs have a long way to go.

CONTACT: 616 791-8540

Less

Ever Wonder How Billions

of COVID 19 Vaccine Vials

are Made???

This video takes you through the highly automated process including the critical AGV transportation of the vial batches between processes. The AGVs automatically pick up & drop off containers loaded with vial trays providing precision placement for robotic process interfaces. Thousands of vials are transported time.

Wondering whose AGV technology provided the capabilities required in this demanding application??? Capabilities such as …. interference-free, virtual navigation, critically accurate station/load positioning, integration with production control systems automatic AGV dispatching, highly efficient AGV traffic & routing control for short travel & response times, remote visual monitoring, etc.

Well, fast forward to times 2:13 and 4:11 (after the ad) in the clip and logos on the vehicles provide your answer.

CONTACT: 616 791-8540

Who Invented the AGV and Has Been in the Business the Longest (….and why)???

Arthur M. (Mac) Barrett Jr. invented the AGV in 1954 and founded Barrett Electronics, Inc. to produce AGVs (then called Driverless Vehicles). That business would ultimately become Savant Automation, Inc. which continues his business legacy of supplying efficient, affordable, low maintenance and well-supported AGV systems for a wide range of material handling applications.

For over 70 years our AGV business has been an industry leader because we maintain control of our technology. What differentiates Savant from others is we have always been a ‘full-service’ AGV business with our own in-house developed, state-of-the-art AGV/AMR technology, our own manufactured vehicles, provided all project implementation services and supplied all parts & service aftermarket support for our customers.

Read More...

Long term support is critical to any system end-user. Will their system technology be supplier-supported 10 or 20 years from now? A system supplier can’t truly be the technology support expert to the end-user, if their core AGV/AMR technology was licensed from a 3rd party who can decide to discontinue that technology. Nor can that licensee easily deal with inevitable component obsolescence issues. That could leave those end-user systems at serious operational risk.

Savant does not license critical core technology from disconnected 3rd parties putting our customers at risk of not receiving the adequate support during their system’s lifetimes.

The best AGV/AMR system insurance for long term support is to contract directly with the ‘Technology OEM’ type system supplier (like Savant) rather than the ‘Technology Licensee’ type system supplier that only uses an OEM’s technology for your system.

CONTACT: 616 791-8540

Less

Are You Spending Too Many $$$’s Manually Moving Loads in Your Facility?

Automate repetitive transportation with standard (i.e. affordable & reliable) AGVs. The base chassis AGV units in this video are configured with a separate powered roller deck load handling attachment.

These attachments are designed for your loads (pallets, racks, rolls, skids, etc.) and have capacities up to 15,000 lbs. As a roller deck configured AGV the vehicle interfaces with both powered and non-powered conveyor pallet pick and drop locations.

The AGV control system integrates with 3rd party MES, WMS, WCS systems to automatically direct AGVs for load pick and drop missions.

Our PC program executes path route & operational changes in mere minutes.

Read More...

Unlike natural feature/AMR type navigation, these AGVs do not need special stand or floor mounted steel bracket targets (monuments) to accurately position for automatic load pick or drop operations. So, there are no ‘trip hazard’ type navigation aids. Most importantly, Savant AGVs can maneuver in very tight spaces and perform exceptionally efficient traffic control that allows higher load move throughput rates than possible with other technologies.

Don’t be tricked!!!

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there’s Zero path maintenance and no navigation reference vulnerabilities that stop other types of AGVs/AMRs.

Remember…. If an AMR can’t see walls (it’s primary reference) at least 80% of the time, it can stop navigating! So things that move around off-aisle in your facility (pallets, racks, forklifts, carts, etc.) and block line-of-sight to the ‘natural feature’ references AMRs depend on, will create frequent and unpredictable navigation stoppages. You don’t want deal with that randomly occurring every day. It ‘kills’ the whole premise of an automated system if people have to constantly intervene because of random events causing vehicle stoppages that interrupt critical load transportation processes in your facility. That can’t happen with Savant AGVs because our ‘references’ are simple markers in the floor that are always visible to the AGVs.

There is no substitute for guided/autonomous vehicle automation experience and given we invented the AGV in 1954, Savant has been in the business way longer than anyone. It’s why Savant’s AGV in-house developed technology (vehicles, navigation, control system) is rated so superior to all others. In fact, most other AGV/AMR suppliers don’t make the core technologies in their vehicles/system. Rather, they license it from a disconnected 3rd party……think ‘obsolescence & support risk’. Savant supports its technology regardless of how old it is…….. because we develop every generation of our technology in-house.

CONTACT: 616 791-8540

Less

Check Out this Video of Savant ‘Tape, Target and Structure-Free’ AGVs …

Versatile, ‘universal-use’ chassis allows Savant utilize the same, proven AGV design for many different types of applications using powered load handling attachments appropriate for each customer’s needs. It’s only the load handling attachment that changes NOT the critical AGV. The less an AGV is custom designed……the better.

Customer benefits of a standard AGV ‘attachment-configurable’ chassis are……..lower Price, more Reliable AGVs, less Maintenance, Proven performance, Re-Purposing same AGV for new applications (truly Reusable Asset), lowest system project Risk, most User-Friendly/User-Tolerant operation, and More.

Read More...

There is no substitute for guided/autonomous vehicle automation experience and given we invented the AGV in 1954, Savant has been in the business way longer than anyone. It’s why Savant’s AGV in-house developed technology (vehicles, navigation, control system) is rated so superior to all others.

In fact, most other AGV/AMR suppliers don’t make the core technologies in their vehicles/system. Rather, they license it from a disconnected 3rd party……think ‘obsolescence & support risk’. Savant supports its technology regardless of how old it is…….. because we develop every generation of our technology in-house.

Unlike natural feature/AMR type navigation, these AGVs do not need special stand or floor mounted steel bracket targets (monuments) to accurately position for automatic load pick or drop operations. So, there are no ‘trip hazard’ type navigation aids. Most importantly, Savant AGVs can maneuver in very tight spaces and perform exceptionally efficient traffic control that allows higher load move throughput rates than possible with other technologies.

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

Less

Platform Lift AGVs

Automatically Transport Carts,

Skids and Pallets

Platform Lift AGVs Elevate Low Underside Clearance Carts and Skids for Floor-to-Floor Automated Transportation

The AGV lift platform is an attachment and is the only part of the AGV that is custom designed specific to the customer’s load requirements. The same chassis is used for all customers which means it’s a very high uptime, standard design with many 1,000’s of hours of proven operation is all types of industrial and commercial facilities.

These AGVs operate in industrial or hospital facilities. The AGVs back under loads, lift and transport carts, pallets or skids to new areas. Virtual path navigation is infinitely scalable (unlimited path length, complexity, destinations and vehicle additions) allowing systems to be expanded in phases.

Vehicles can read RFID tags or barcodes on loads to automatically route to correct delivery destinations.

Networked system monitoring shows current vehicle locations, destinations, battery levels and more.

Read More...

Unlike natural feature/AMR type navigation, these AGVs do not need special stand or floor mounted steel bracket targets (monuments) to accurately position for automatic load pick or drop operations. So, there are no ‘trip hazard’ type navigation aids. Most importantly, Savant AGVs can maneuver in very tight spaces and perform exceptionally efficient traffic control that allows higher load move throughput rates than possible with other technologies.

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

Less

‘AGV Poetry In Motion’…

‘Tape-Free’ Low Profile AGV

with Lift/Lower Deck

Another attachment type using the Savant Universal-Use AGV. The lift/lower platform is powered by the low-profile AGV pinned underneath. This allows the AGV transfer loads to/from simple & inexpensive static load stands or conveyor with split roller/open center access.

Savant AGV support all functionality required for fully automatic, ‘hands-off’ operation. This includes failsafe interlocking with powered doors, light curtains, conveyors, and robots and interface with forms of station I/O that generate AGV pickup calls such as HMI’s, tablets, pushbuttons and load sensors at load pickup stations. The AGV system controller (PC) supports integration with upper-level control systems (MES, WMS, WCS, PLC networks, etc.) for remote AGV ‘call & dispatch’ operation.

Read More...

Note the traffic control functionality that permits multiple vehicle movement in tight, complex virtual path areas. Less capable technologies severely restrict AGV/AMR freedom of movement. The COST to you….poorer response time (longer load move wait times), lower system efficiency (less loads moved per hour per vehicle), all negatively impacting your facility’s operational performance.

Unlike natural feature/AMR type navigation, these AGVs do not need special stand or floor mounted steel bracket targets (monuments) to accurately position for automatic load pick or drop operations. So, there are no ‘trip hazard’ type navigation aids. Most importantly, Savant AGVs can maneuver in very tight spaces and perform exceptionally efficient traffic control that allows higher load move throughput rates than possible with other technologies.

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

Less

‘Tape-Free’ Low-Profile AGV

with

Powered Roller Deck

Universal-Use, AGV can be configured with various types of load handling attachments. Here the AGV is attached to a powered pallet roller deck. The roller bed attachment is plugged into the AGV for power and control signals.

Standard, low-profile AGV models provide up to 10,000 lbs. capacity. Although the AGVs are standard chassis, the attachments are designed for specific user applications such as multiple load decks, tiered tote decks, and dimensioned as required. Using a standard chassis allows the AGVs to be repurposed with different attachments if future needs change.

Read More...

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight dependent ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

Less

Using ‘Tape-Free’ Low-Profile

AGV to Tunnel Under

& Transport Carts

One of the easiest and most affordable ways to automatically pick and drop loads is to use the Savant Low-Profile AGV to tunnel under a cart, raise 2 powered pins into plastic pin receptacle blocks mounted under the cart and then drive the cart to a new destination. The AGV can navigate forward or backward into cart parking spurs. Efficient & safe multiple vehicle traffic control maximizes system throughput (loads moved per hour per vehicle).

Carts loads can be racks, pallets, boxes, totes, rolls, or other materials. Virtually any size or type cart that has the minimal underside clearance to accommodate the low-profile AGV can be transported automatically. These AGVs are extremely maneuverable requiring minimal space for cart pick/drop spurs.

Read More...

ALL guided vehicles (AMRs, AGVs, AGCs) require some type of navigation references. Savant’s ‘Virtual Path’ navigation uses no floor tape, reflective targets or line-of-sight depending ‘natural features’ (walls) so there is Zero path maintenance and no reference vulnerabilities that stop other navigation technologies. Path route & operational changes are executed with a visual path PC model program and uploaded to the PC system controller allowing your system to be altered in mere minutes.

CONTACT: 616 791-8540

Less

Savant

Counterbalanced

Fork AGV

Savant counterbalanced fork and attachment-configurable AGVs accurately navigate without targets, tape, or natural feature/structural dependence. Compared to others these units are compact, robust, less complex and lower cost.

Zero-maintenance ‘virtual path’ means NO vulnerability due to real-world factors such as blocked line-of-sight references, lighting conditions, nav. sensor/reference damage, dust on vision or laser type sensors, etc.

CONTACT: 616 791-8540

Safe, Affordable,

Automated

Material Transportation

Compact counterbalanced fork AGV can service loads at floor level to heights of up to 10 feet. ‘Virtual Path’ CAD map navigation requires no tape, targets or dependence on often blocked ‘natural feature’ (walls, facility structures). Quick, easy, inexpensive to change system routes, destinations and add vehicles as needs require.

CONTACT: 616 791-8540

Savant Low-Profile,

‘Tape/Target/Structure-Free’,

Virtual Path AGVs

A fleet of over 30 Savant low-profile, ‘tape/target/structure-free’, virtual path AGVs automatically transports different size/purpose carts between hundreds of destinations. Racks, totes, shelf, pallet, kitted and trash carts are moved on demand assuring labor-efficient, timely service to all plant areas. Unlimited scalability coupled with zero navigation vulnerability downtime has significantly reduced costly & non-value adding labor.

CONTACT: 616 791-8540

‘Tape-Free’ Low-Profile AGV

with

Powered Roller Deck

Savant’s Visual Path Configuration program creates simulation of your AGV system operating in your facility. See vehicles performing actual traffic control, shortest route between destination and station actions. Confirm system operation before uploading model file to actual system controller. Infinite system scalability and ‘bullet-proof’ navigation with no line-of-sight dependence vulnerabilities to blocked building structure.

Read More...

‘Tape/Target/Structure-Free’ navigating automatic guided vehicles allow unlimited system size and complexity. AGVs track CAD map created with standard PC program allowing quick and inexpensive system changes. Unlimited scalability and flexibility.

CONTACT: 616 791-8540

Less

Just as people have come to see EVs not equivalent to internal combustion automibles for all uses, the same applies to AMRs and AGVs.

AMRs are not AGVs when it comes to industrial material handing automation in factories and warehouses!!! We know because we’ve been in the business since we invented the first guided vehicle in 1954… 70+ years ago.

All guided vehicles (AGV, AMR and AGC) need navigation references. If those references are vulnerable in certain environments… the guided vehicles can’t navigate and the materials they are there to move… don’t get moved (costing unrecoverable $$$$’s).

AMRs use line-of-sight to walls (primarily) and fixed structures (secondarily) as references. Most system use areas in factories & warehouses are far from walls making consistent and accurate navigation (needed for automatic load pick/drop) randomly problematic.

Read More...

That’s because other things are moving outside of the vehicle’s path and randomly interfering with their critically needed line-of-sight to their ‘natural feature’ references.

That never happens with Savant AGV technology because our navigation references are part of the floor, protected and unblockable.

Nothing else matters if the the guided vehicle navigation reference technology is vulnerable and a poor match for the facility environment.

Savant’s bulletproof navigation references combined with our robust, load-attachment configurable vehicles is without question, the best solution match for factory and warehouse automated material transportation needs

US-based, Savant develops and owns its AGV technology and manufactures our unique universal-use vehicles. We are a full service AGV system supplier providing all project services as well as 24/7 aftermarket support.

Our history began in 1954 with the invention of the AGV. ISO-certified, we have supplied systems for manufacturing, warehousing, distribution, paper, plastic, pharmaceutical, food, beverage, healthcare/hospital, etc. markets.

CONTACT: 616 791-8540

WEBSITE: www.agvsystems.com

Less